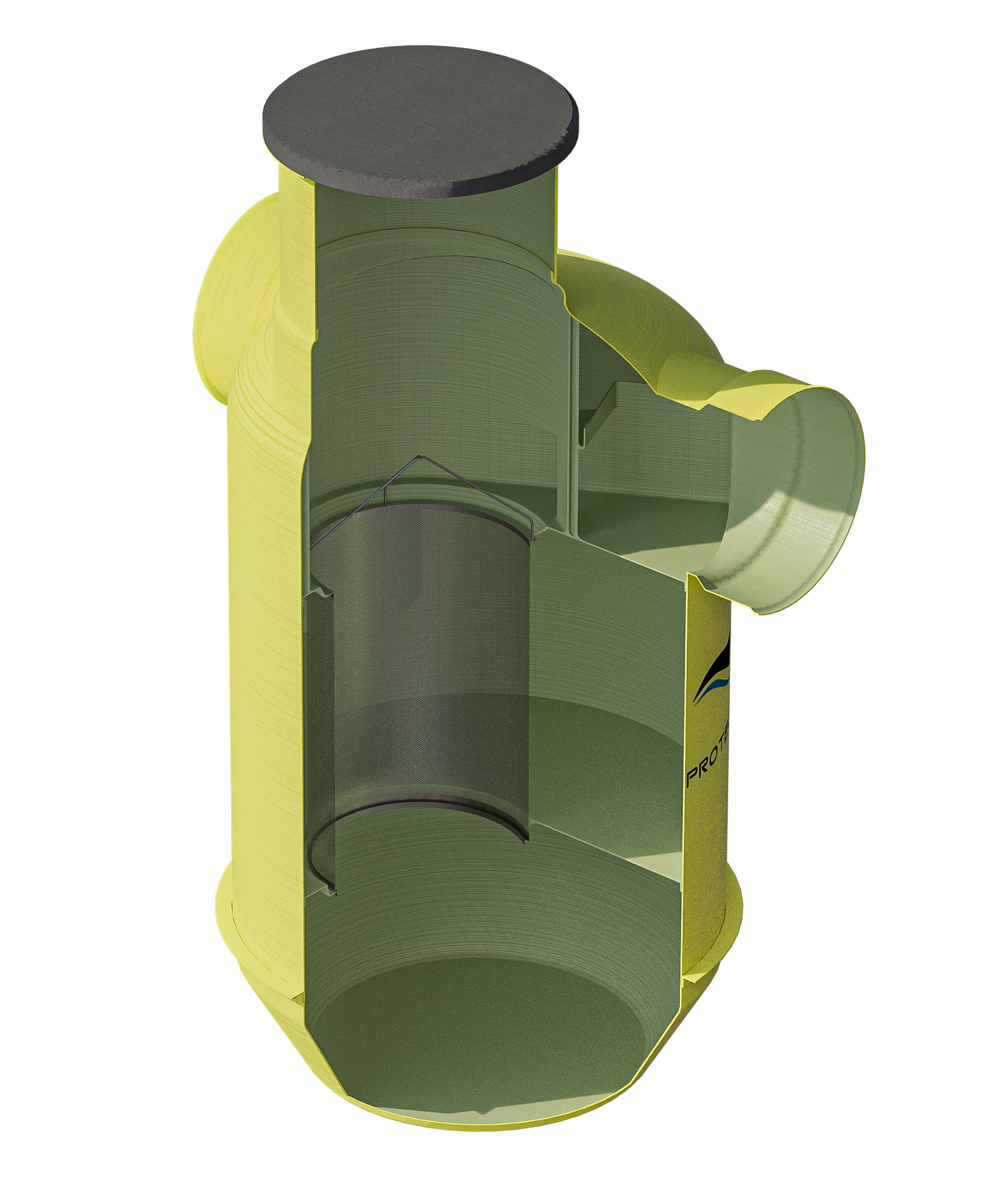

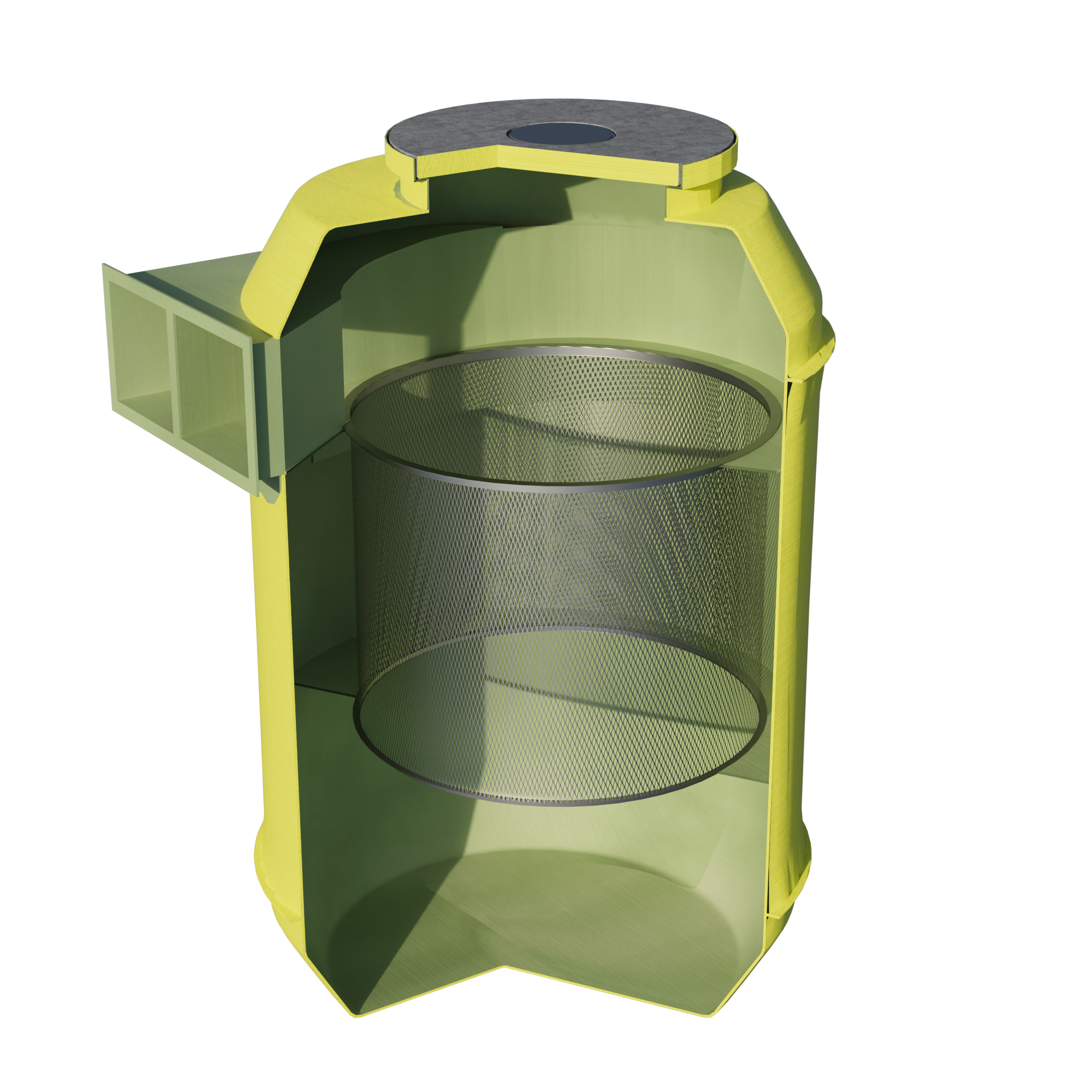

TRAP INSERT

POLLUTANT TRAP

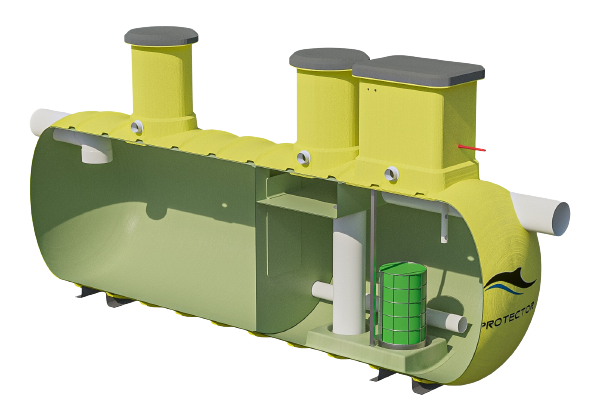

DEFLECTION SEPARATION GPT

CONTAINMENT AND OIL SPERATION

STORMWATER TREATMENT

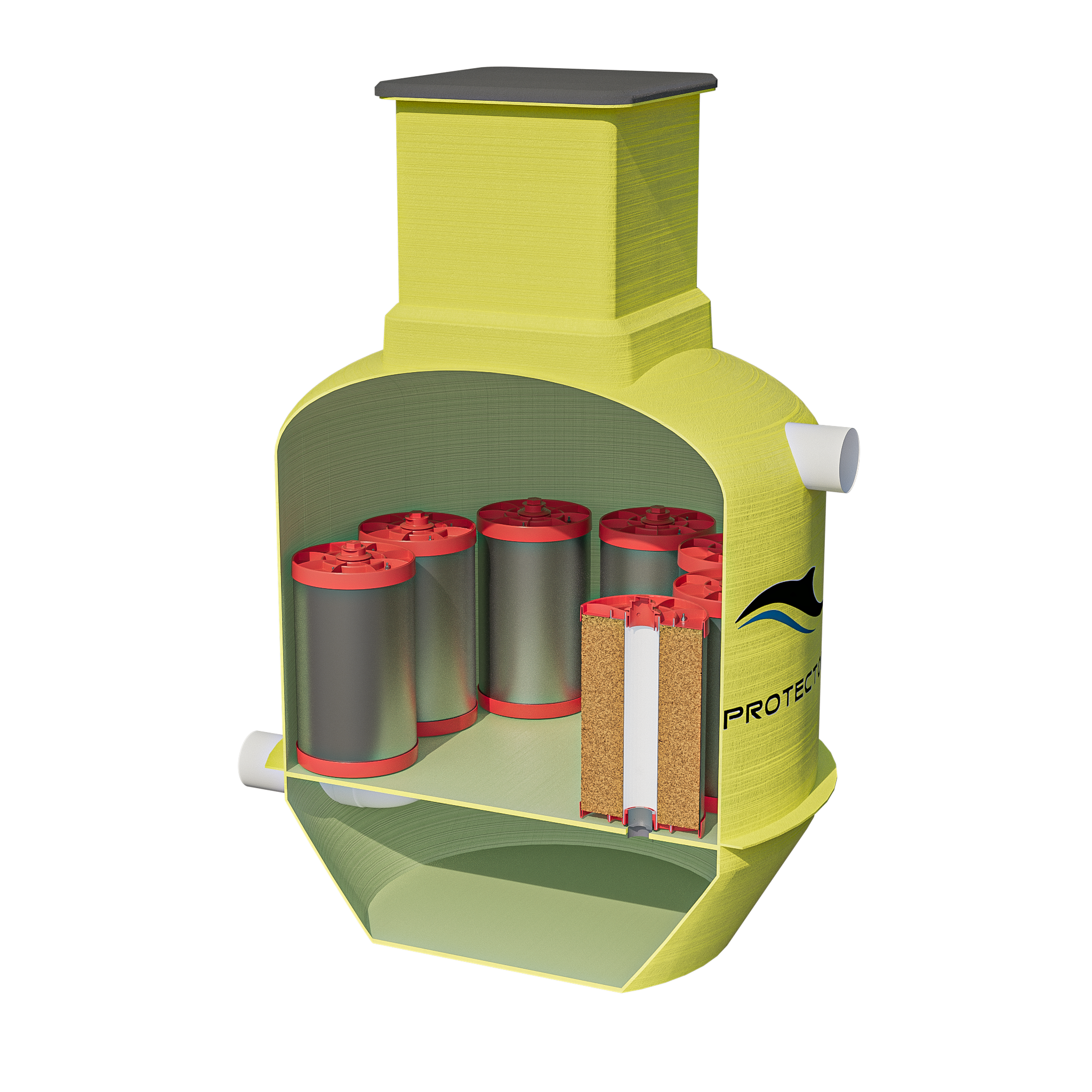

TERTIARY FILTRATION

WITH OFFLINE FILTRATION

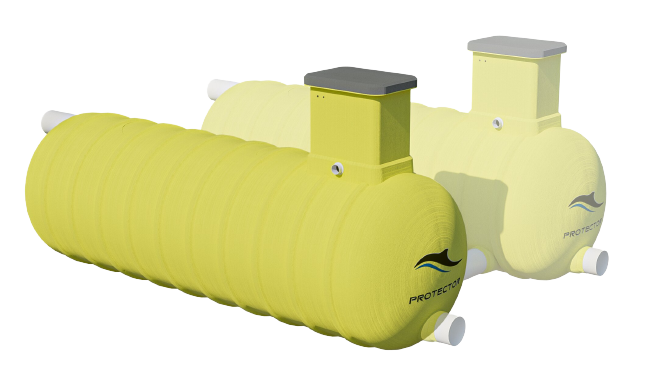

FRP LIQUID STORAGE SYSTEMS

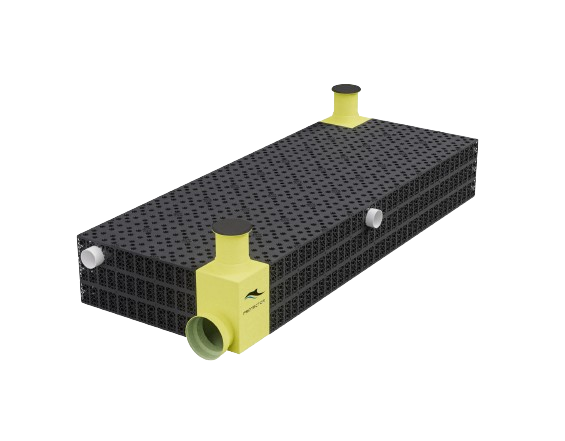

RETENTION SYSTEMS

HYDRAULIC NUTRIENT

FILTRATION SYSTEM

Who is Protector

Protector is a family-run Australian company that specializes in treating stormwater and making fiberglass products. With 18 years of experience, they focus on improving their designs and manufacturing processes. Their stormwater treatment products meet high Australian standards and are known for their quality. Protector has simplified installation by removing the need for confined space entry and deep digging.

Our products are made using a special process that makes them strong in all directions. Each product has a smooth inner layer that resists corrosion and an outer protective layer. Made from Fiber Reinforced Plastic (FRP), they are lightweight, easy to handle, and durable. FRP is a sustainable material that lasts longer than traditional materials, doesn’t rust, and withstands tough conditions, which means lower maintenance costs and less environmental impact. Protector’s products are strong, long-lasting, and easy to maintain, making them an excellent choice for stormwater treatment.

To read more about Protector and their stormwater treatment solutions, click here.

At Protector, we are focused on improving the quality of our waterways by supplying products that are designed to capture and contain pollution in stormwater runoff for many applications. Contaminants such as hydrocarbons, suspended solids, plastic rubbish, and dissolved nutrients are removed by utilizing absorption, retention, filtration, and capture processes. These stormwater systems will deliver cleaner water back into the environment, saving nature for future generations.

SAVING NATURE

At Protector, we are focused on improving the quality of our waterways by supplying products that are designed to capture and contain pollution in stormwater runoff for many applications. Contaminants such as hydrocarbons, suspended solids, plastic rubbish, and dissolved nutrients are removed by utilizing absorption, retention, filtration, and capture processes. These stormwater systems will deliver cleaner water back into the environment, saving nature for future generations.

Download Our Capability Statement

Protector’s products are well known for their exceptional quality, and they meet the rigorous standards set by both Australians BS-4994-1987 and ASME RPTI. Additionally, Protector has made device installation much simple by removing the need for confined space entry and base excess during site excavations. To ensure that each product meets specifications.

Protector have rigorous quality control procedures in place. Each unit is inspected and factory tested according to industry standards after production.

Protector’s products are created using the advanced chop hoop filament winding process, which guaranteed both longitudinal and circumferential strength. Moreover, every product has a smooth molded resin-rich inner corrosion barrier layer and external resin barrier made from FRP(fiber-reinforced plastic). Protector’s products are lightweight, easy to manage, and simple to install.

FRP composites are an eco-friendly material and their physical properties result in a more extended service life than traditional materials. Their weight savings benefits reduce construction and transportation expenses, reducing the environmental impact.FRP products are incredibly robust and resistant with the effects of aging, weathering, and harsh environments, making them far more durable far than other materials. Furthermore, the molded internal finish offers superior protection against scum accumulation, and FRP is not prone to rust, providing products an excellent corrosion resistance and reducing maintenance requirements.

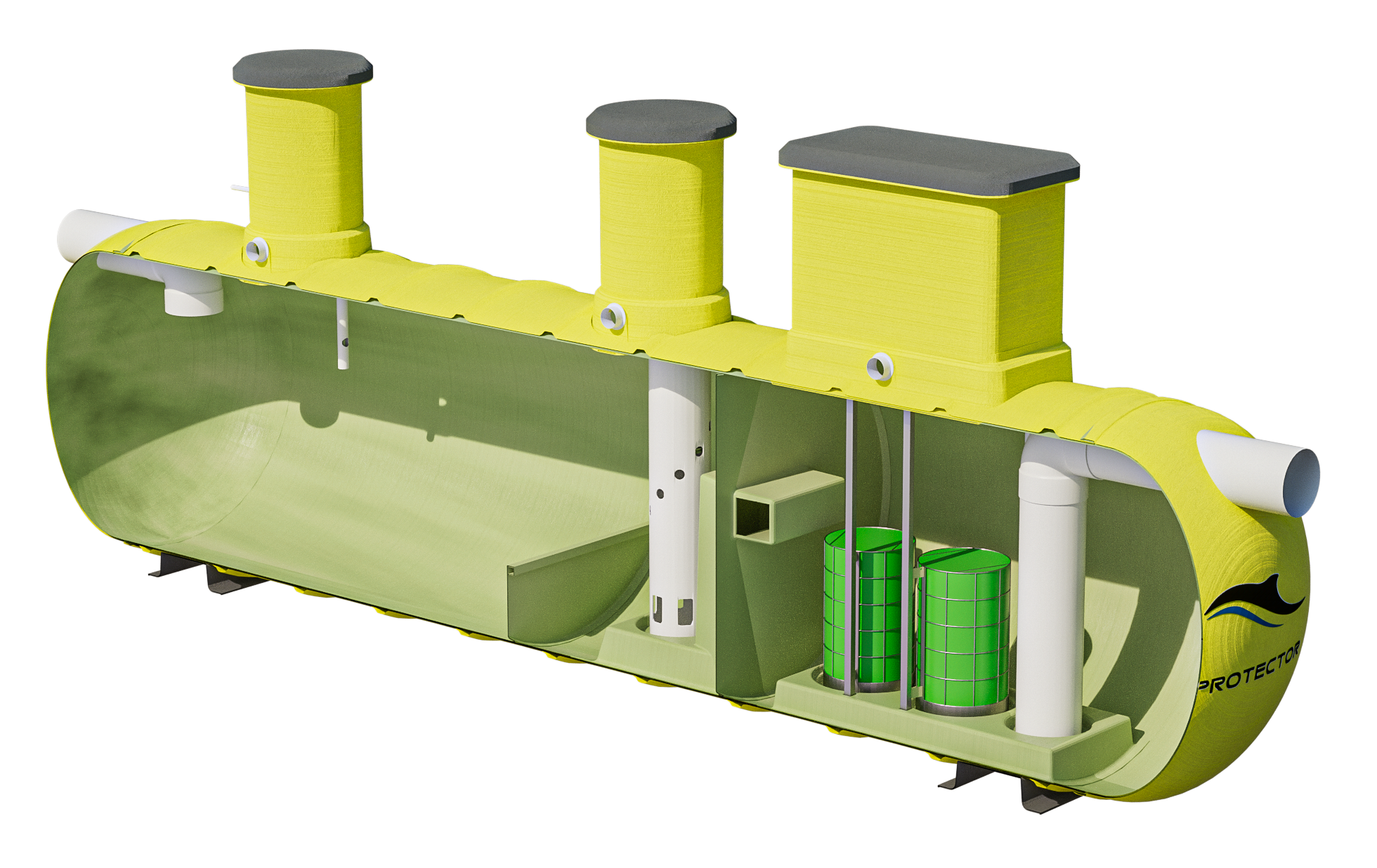

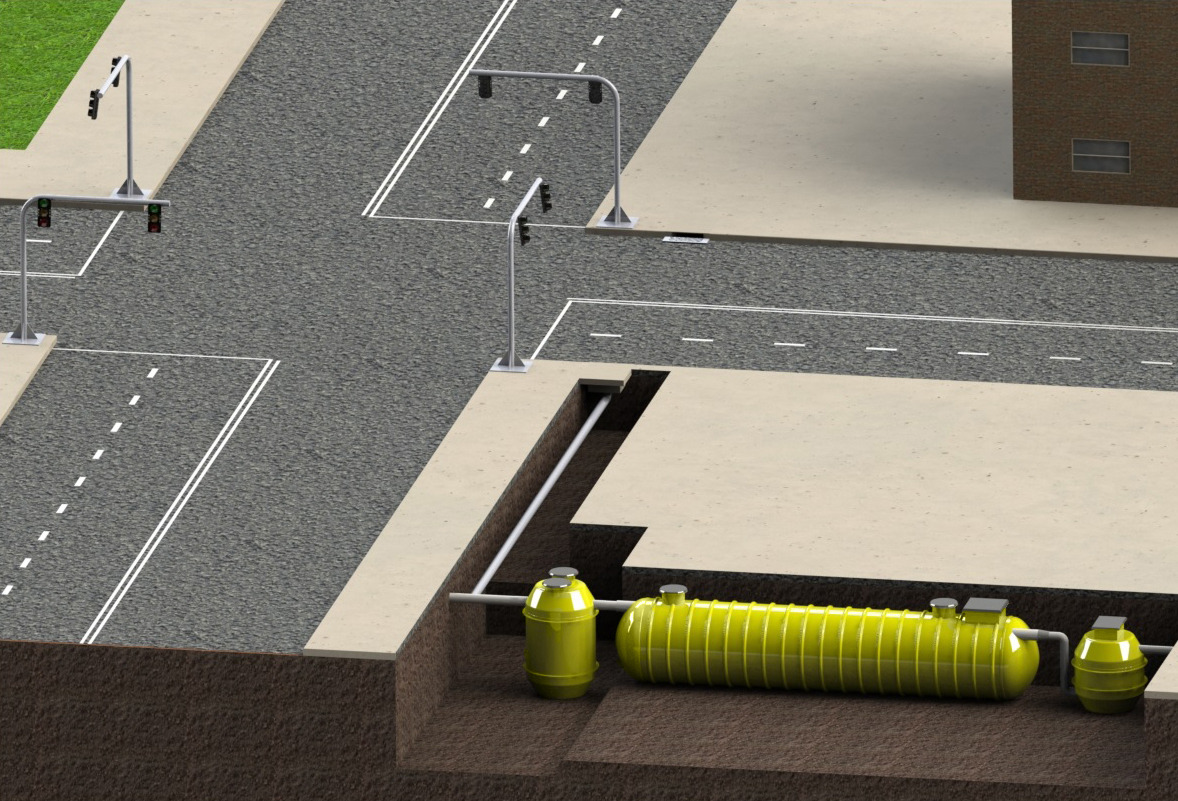

Treatment Trains

Treatments trains, consisting of a series of stormwater treatment systems are designed to ensure that all necessary environmental treatment requirements are met for a given site. Our Protector products are renowned for their high quality and meet both Australian standards BS4994-1987 and ASME RPTI.W have also made installation easier by eliminating the need for confined space entry and access to the base of the site excavations.

Our quality control procedures ensure that each product is manufactured to exact specifications, and each unit undergoes post-production inspection and factory testing to industry standards. Constructed using the advanced chop hoop filament winding process, our Protector products are both longitudinally and circumferentially strong. They feature a smooth molded resin-rich corrosion barrier layer and an external resin barrier and are manufactured using sustainable FRP (fiber-reinforced plastic), making them light weighted, easy to handle, and easy to install.

FRP composites offer weight-saving benefits, lowering construction and transportation cost while reducing environmental impact. They are highly durable and far more resistant to aging, weathering, and degradation in severe environments than traditional materials. Maintenance is simplified by the smooth internal molded finish, providing superior protection against scum accumulation, and FRP is not susceptible to rust, offering excellent corrosion resistance. These characteristics make our Protector product an excellent choice for inclusion in treatment trains, enabling them to remove all necessary contaminants from the water flow while protecting tertiary and finer treatment systems from clogging and increased maintenance requirements.

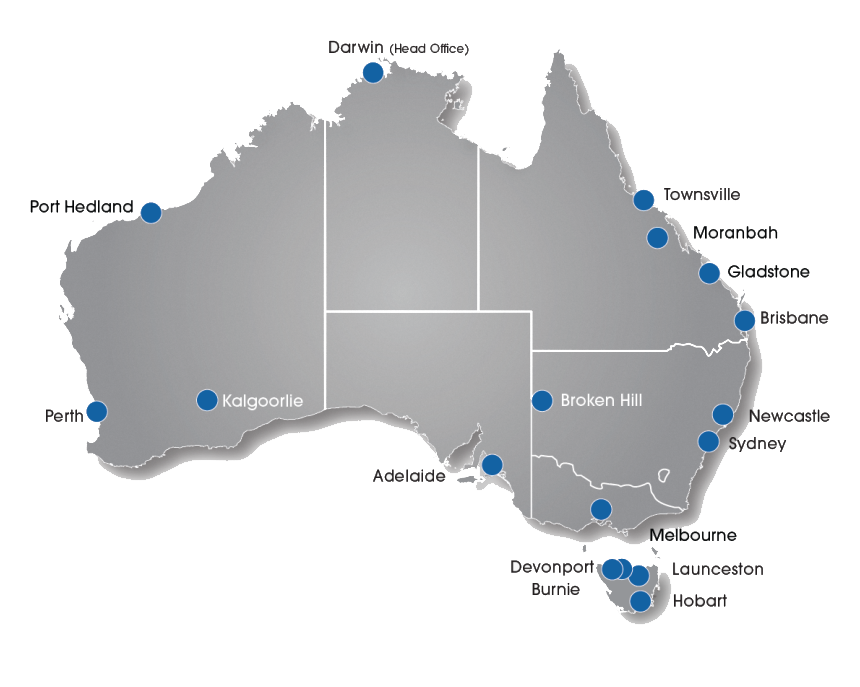

We install and service Australia wide.

Service

Agents

Recent Projects

Here are a few of many projects we have completed for our customers. We provide a professional service

which includes consultation, free estimate, design, supply of materials and installation.

THE GANGARRI SOLAR PROJECT

Project Description

THE GANGARRI SOLAR PROJECT

Project Description

Coastal View Development Lakes Entrance Project

Project Description

Coastal View Development Lakes Entrance Project

Project Description

Child Care Centre Project

Project Description

Child Care Centre Project

Project Description

Puma Energy

Project Description

Puma Energy

Project Description

TRIPLE CHAMBER SEPARATOR Diameter: 2200mm Total length: 11,000mm Oil Capacity: 9000L Silt capacity: 1000L Coalescer Filter Type: R6 Filter flow rate: 35L/sHYD.015.3C-R2.A HydroProtector

TRIPLE CHAMBER SEPARATOR Diameter: 1500mm Total length: 6000mm Oil Capacity: 1500L Silt capacity: 300L Coalescer Filter Type: R2 Filter flow rate: 5L/s

Explore Our Recent Projects

Enquire with us

Today!

Call 1300 585 787