Treatment

Train System

Treatment

Train Systems

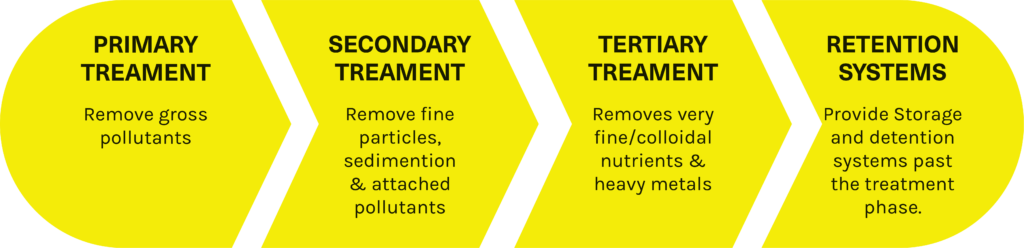

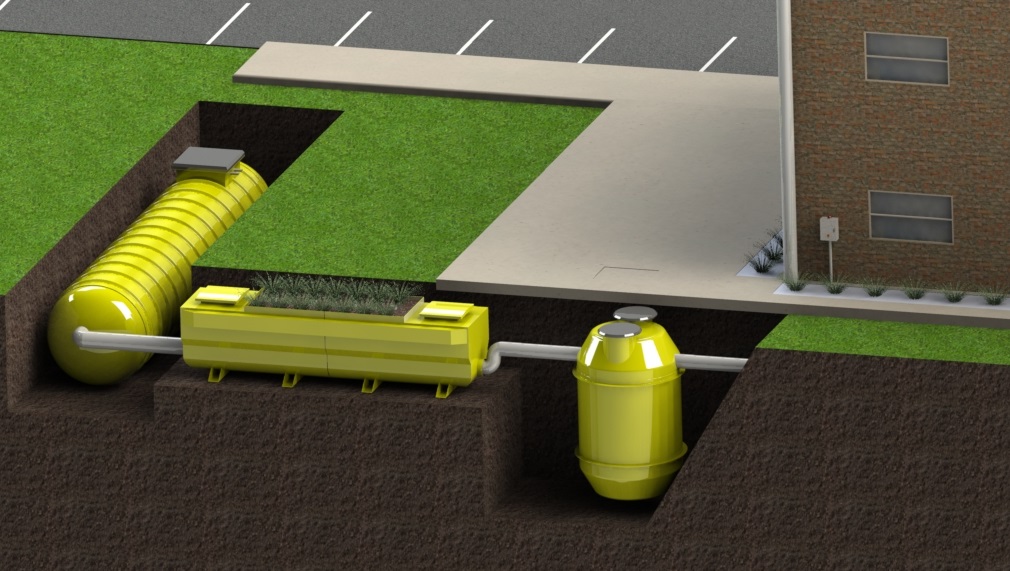

The concept behind the use of Treatment Trains, being a series of stormwater treatment systems, is so that the total system of the site in question covers every environmental treatment required. The Protector systems come easily combinable to foam treatment trains in such a way to remove all the required contaminants from the water flows, as well as protecting the tertiary and finer treatment systems from clogging and increased system maintenance. The usual need for the use of Protector Treatment Trains come in the shape of requiring to cover a wide range of pollutant removal and the need to reach a certain percentage of contaminant remaining as in stormwater as set by environmental government standards, specifically in oil removal and hydrocarbon reduction. Furthermore, these treatment trains may be required to have large retention system for storage, as well as pumping stations to ensure that the flow of stormwater and its treatment is constant and controlled.

THERE ARE 4 LEVELS OF TREATMENT ACCORDING TO THE TEAM AT PROTECTOR. THESE CONSIST OF:

PRIMARY TREATMENT

SECONDARY TREATMENT

TERTIARY TREATMENT

RETENTION SYSTEMS

With the mining industry being the second largest industrial water usage sector in the world, there is a dire need to completely and successfully filter and maintain the water quality in these areas. Water management is critical in mining, and due to the high standards instructed in the Australian industry in mining, rigorous systems must be used. The treatment of water for these sites can then be used to be implemented in process such as dust suppression, cooling systems such as in boilers, reuse in non-drinking purposes, vehicle washing and wet screening. Due to these requirements of reuse of water a high filtration percentage is not required and hence several primary and secondary systems in conjunction with retention systems.

There is also a large amount of waste water produced in these systems, mainly in the form of sedimentations and hydrocarbons. In any situation where the water that is being treated is not being reused in site activities as previously stated, we recommend the use of tertiary treatment systems as an aim to reduce the heavy metal percentage upon discharge into the environment. In this case we recommend the use of the Enviroprotector system for these such situations.

Hence it is recommended that the Hydroprotector systems be used in attempts to reduce hydrocarbon percentage and remove fine sedimentations from the water systems and the use of our pumping station retention tanks to move the water throughout the site.

This treatment train system can also be applied to:

- Building sites

- Petrol stations

- High industrial areas

- High locations of hydrocarbon production

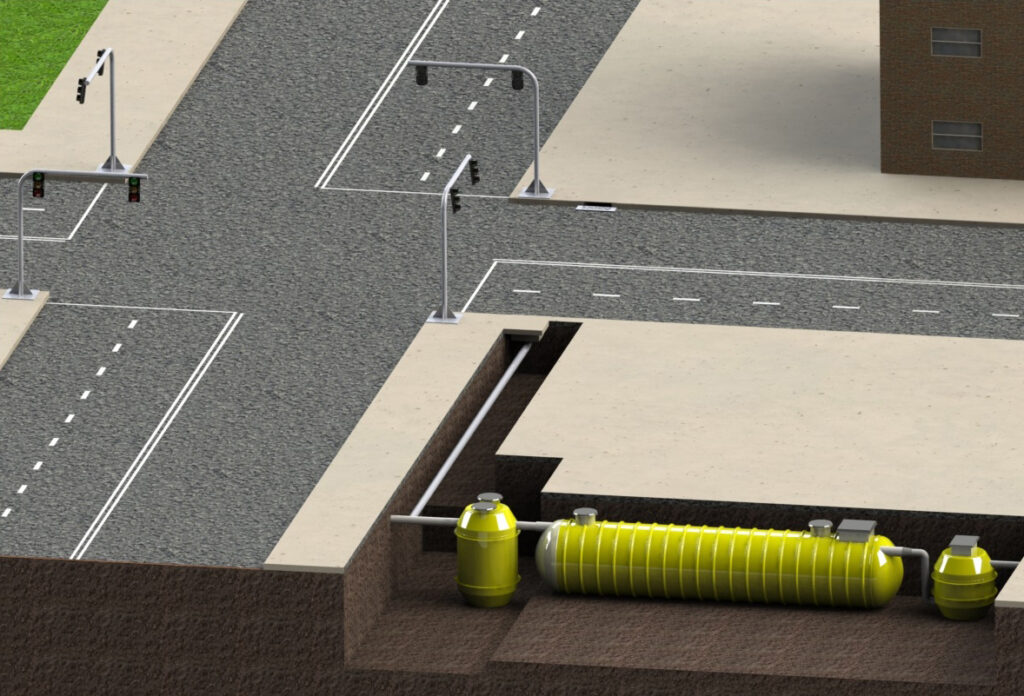

High traffic areas have a series of pollutants that remain a big issue in treatment of these systems. High traffic areas produce contaminants such as high amounts of hydrocarbons, high levels of gross pollutants, heavy metals and fine sedimentation. Hence solutions are required to remove these pollutants are produce water for the environment with as low percentages as possible. Hence a combination of primary, secondary and tertiary, and depending on the weather conditions and flow rates of the area, retention systems.

We recommend the use of the Ecoprotector, Stormprotector and any of the Enviroprotector and the Xtreamprotector. These tertiary treatments use modern filtration media and techniques to remove high percentages of the heavy metals in these water ways. They also have the capacity to remove all colloidal particles and fine sedimentation that go through the first two stages.

Areas in which these systems can be used are also:

- Tunnels

- Airports and Tarmacs

- Rooftop runoff and rainwater treatment systems

- Industrial estates

- Transport depots and loading bays

- Highways and any areas of high traffic

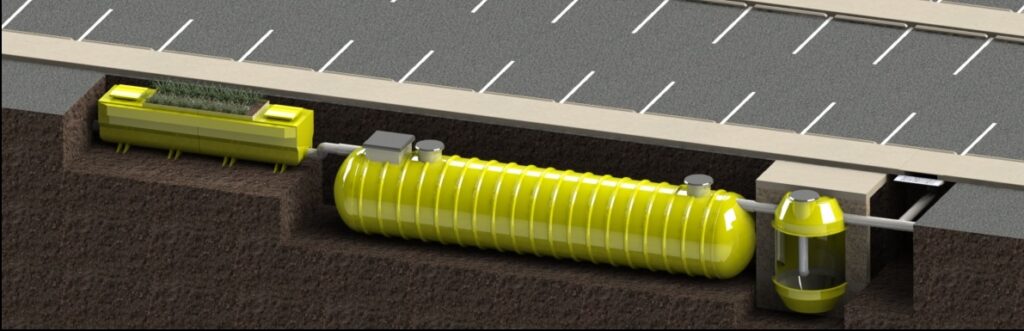

Carparks and urban developments, have the tendency for high levels of oils, hydrocarbons, and heavy metals produced from cars and rooftops. These areas need to be thoroughly treated discharged back into the environment as usually is the requirements for water treatments in these areas. Hence the Tertiary Treatment Systems are required for these areas, with all of the Protector tertiary designed systems removing the required contaminants that are produced from these areas.

Application in which this system train will be effective, mainly in conjunction with the Bioprotector, are considered to be:

- Urban settings

- Shopping precincts and carparks

- Industrial areas

Residential systems require a fair amount of filtration, but not to the drastic level of high industrial areas, high traffic areas, and fueling areas. Due to a lack of high oil percentages, it is not a requirement for the secondary filtration systems that provide the most efficient Hydrocarbon removal systems to be implemented, instead the use of gross pollutant traps and tertiary treatment. The BioProtector system is recommended for these areas due to its ability to fit into urban design settings as well as providing natural filtration processes. It is able to remove high enough levels of hydrocarbons and heavy metals as would be required. As well as removing phosphorus, nutrients, and organic compounds naturally. This system is recommended in use anywhere expelling directly into environmental systems is likely and required.

Due to the high distance needed to travel and head required in these sorts of environments, A Hydrovault with a pumping station incorporated is recommended. Retention is a common requirement for residential and municipal estates and hence the implementation of these devices is highly recommended.

The applications best suited to this treatment train system also include:

- Residential areas

- Council recreational area

- Beaches and parks

- Natural developments

High industrial areas produce large amounts of wastewater, with this wastewater containing contaminates that are difficult to treat and hence remove. This wastewater is high in heavy loading of contaminants such as heavy metals, as well as being high in salinity. Designing systems that are suitable for the treatment of heavy contaminants and high salinity is vital as this water is expelled directly into the environment or into sanitary sewer systems.

Common sources of industrial wastewater includes:

- Battery manufacturing

- Electric power plants

- Food industry

- Iron and steel industry

- Petroleum refinery

Enquire with us

Today!

Call 1300 585 787