BioProtector

BioProtector Overview

- REMOVE MANY STORMWATER POLLUTANTS EFFECTIVELY.

- VERSATILE FOR NEW OR RETROFIT APPLICATIONS.

- ACCEPT VARIABLE PIPE SIZE OR RUNOFF.

- PRE-FILTER CHAMBER REDUCE MAINTAINCE.

BioProtector

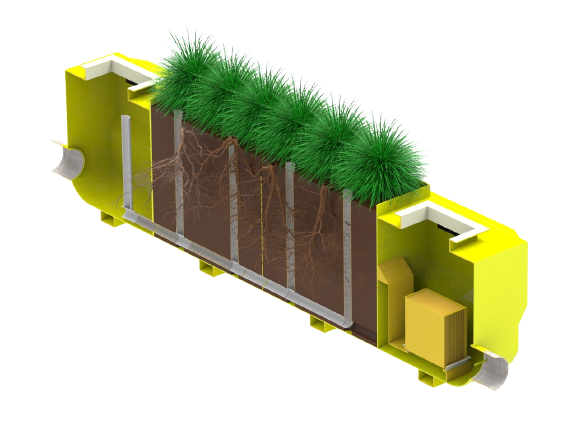

The BioProtector is a stormwater treatment system that combines physical and biological filtration processes to effectively remove various contaminants. This system utilizes the hydraulic flow of stormwater to push water through its dual filtration process, making it suitable for a wide range of applications including streetscapes, parking areas, urban environments, highways, and industrial settings. The BioProtector has a small footprint, making it easy to install in any location or in combination with other Protector products. It can also be installed downstream of detention systems, making it the only biofilter capable of this.

The protector team customizes the Bioprotector to fit the specific need of each site, ensuring that it is the perfect solution.

A BioProtector is a versatile treatment system that can be installed in a wide range of applications, including residential and commercial buildings, pathways, parking islands, and street garden landscapes, with its ability to remove heavy metals such as mercury, lead, and copper, the BioProtector provides a simple effective solution to the cleaning, and treatment of all kinds of stormwater runoff. This system can be on easily retrofitted into a position adjacent to a building, providing an aesthetically pleasing look.

The BioProtector is designed to combine physical filtration with biological filtration, making it highly effective at removing a wide range of contaminants. The entire system utilizes the hydraulic flow of the stormwater to push the water through its dual filtration process. This compact system has a small footprint, making it easy to install in any situation or in combination with other Protector products. In fact, it is the only biofilter capable of installation downstream of detention systems.

The ground-level grate design of the BioProtector allows it to be easily implemented in a variety of settings, providing clean water treatment for runoff from any surface. This grated inlet system is best suited to sump conditions and can be combined with inlet pipe flow systems from upstream catchment basins for increased efficiency. Its inlet can be connected directly to a drainpipe, making it an ideal solution for rooftop runoff treatment.

The Bioprotector utilizes various plants, such as a Common Rush, Matting Lomandra, and Breeze Lomandra, in its filtration system. The root systems of these plants trap pollutants and promote biological activity, breaking down and filtering out harmful substances from stormwater runoff. The Common Rush, for example, can absorb a high level of nutrients, while Matting Lomandra has a dense root system that helps retain water and prevent erosion. The Breeze Lemondra is also effective at nutrient uptake and can tolerate various soil and moisture conditions.

Together, these plants create a diverse and effective filtration media for the Bioprotector, promoting natural water treatment while reducing the need for costly and energy-intensive mechanical filtration systems. The system is also low maintenance, as the plants self-regulate and can even act as an attractive landscaping feature. By utilizing the natural power of plants and their root systems, the Bioprotector offers an eco-friendly solution to stormwater management, protecting the environment while improving water quality.

Product Application

- Urban Streetscapes

- Car Parks & Shopping Centers

- Residential and Commercial estates

Enquire with us

Today!

Call 1300 585 787