Xtreamfilter

Xtreamfilter Overview

- TWO DIFFERENT MEDIA DESIGNED TO TARGET AND REMOVE SPECIFIC CONTAMINANTS.

- PASSIVE HYDRAULIC FILTRATION REQUIRING NO ENERGY INPUT AND MINIMAL ENVIRONMENTAL IMPACT.

- UTILIZES ADSORPTION, ATTACHMENT TECHNIQUES, PRECIPITATION, AND PHYSICAL TECHNIQUES FOR POLLUTANT REMOVAL.

- SELF-CLEANING TECHNIQUES AND BACKWASH FOR MAINTENANCE AND MEETING STRINGENT COUNCIL REQUIREMENTS.

Xtreamfilter

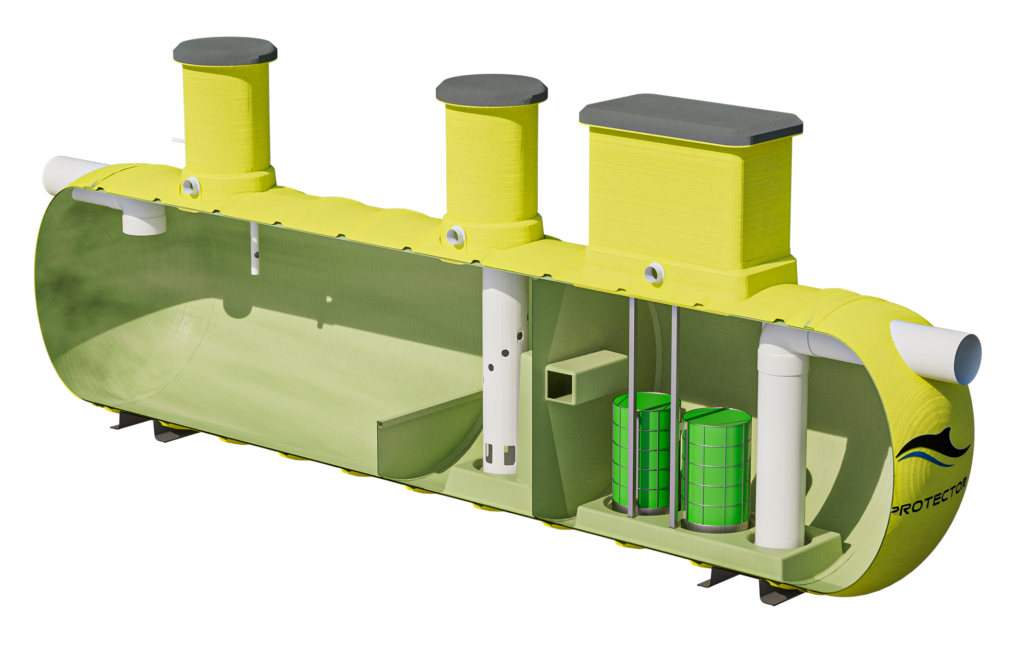

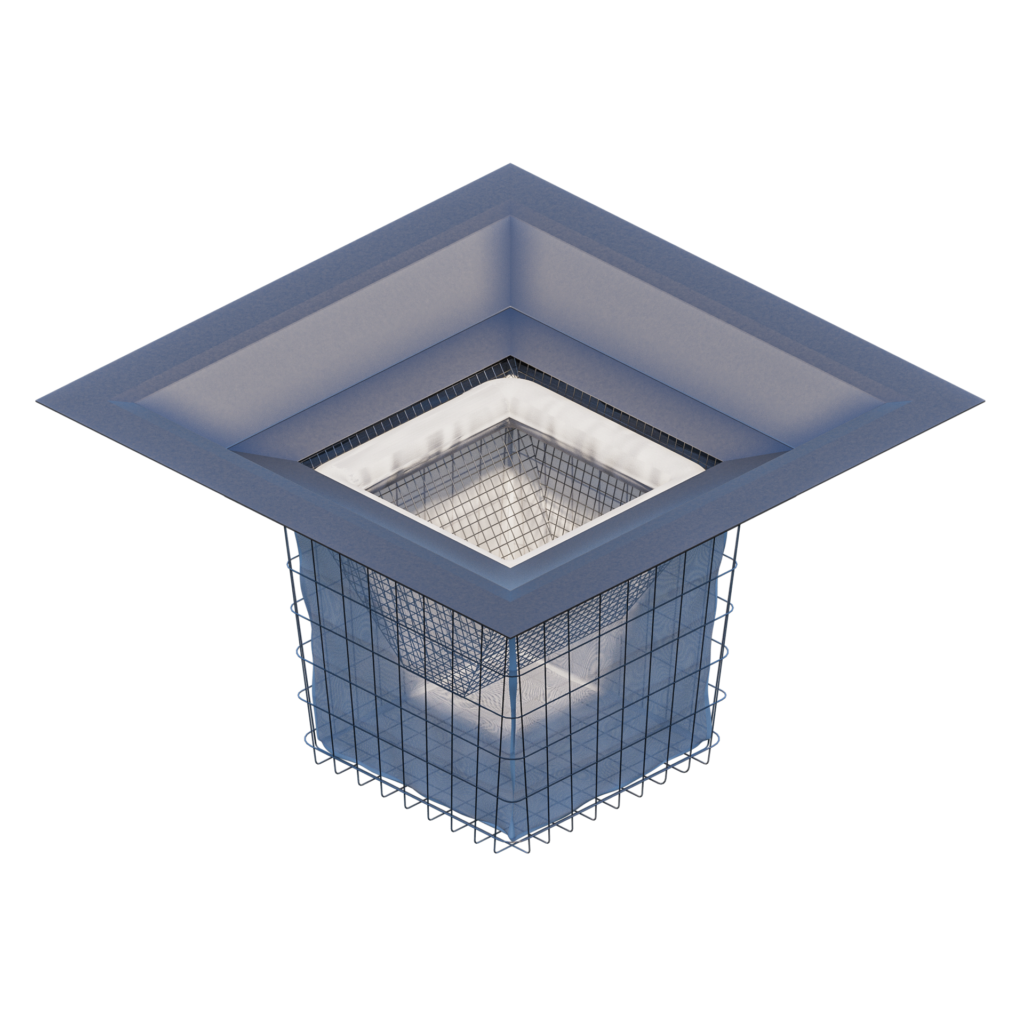

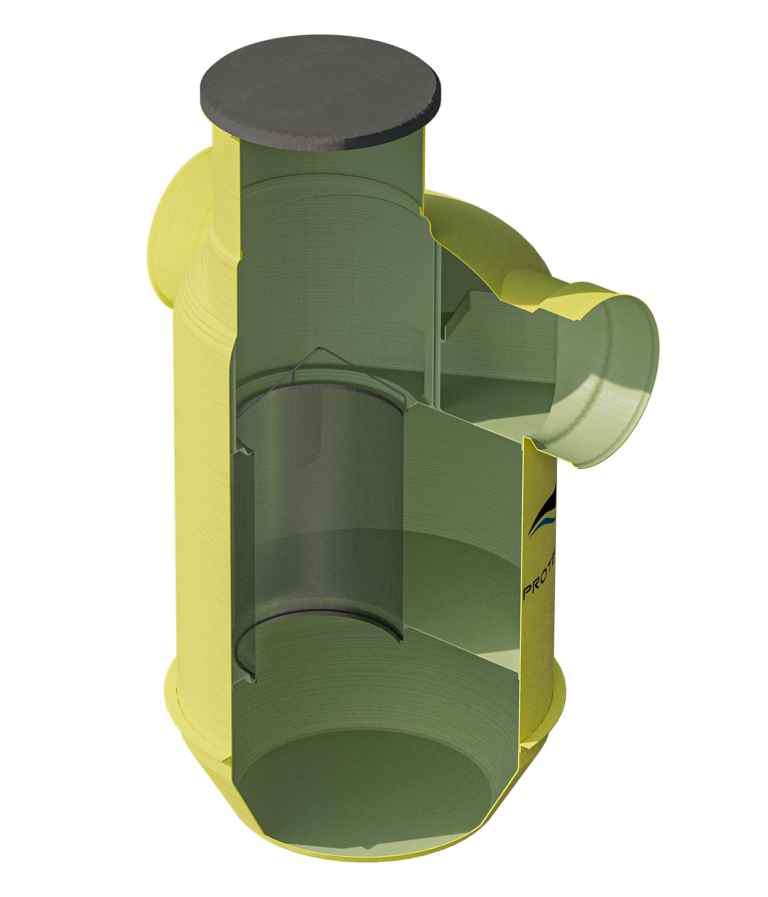

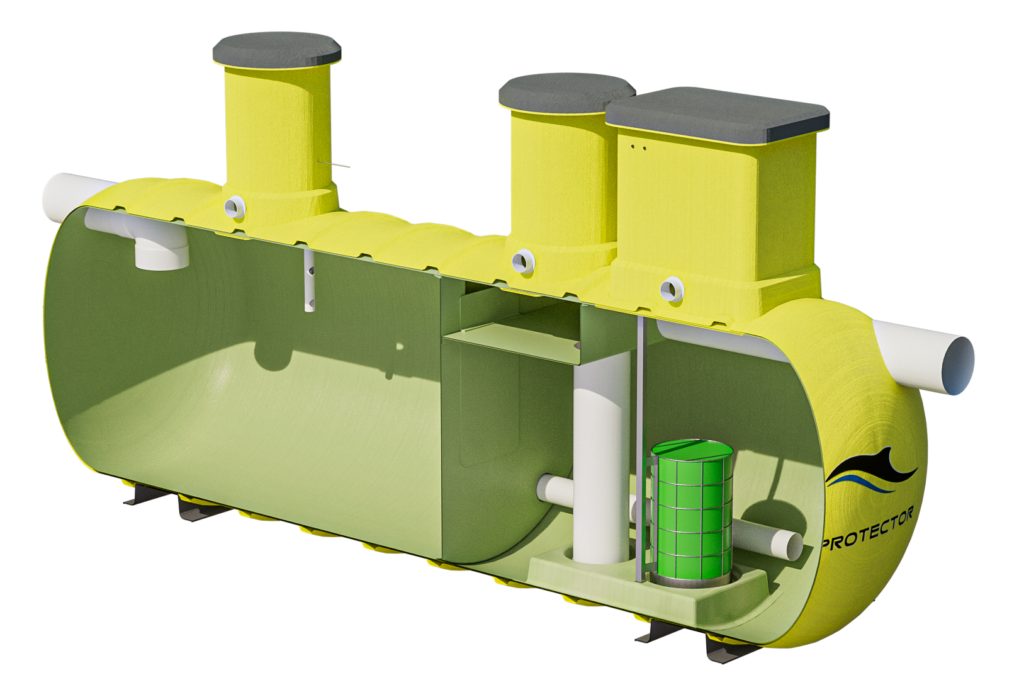

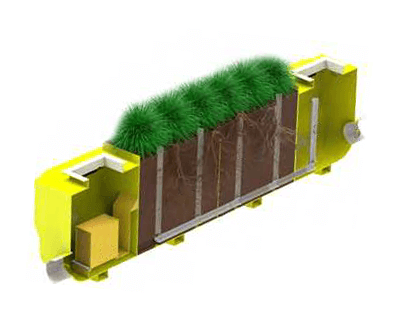

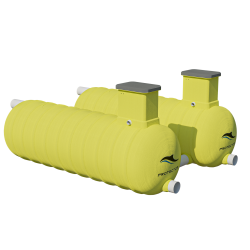

The Xtreamfilter is an efficient filtration system that removes fine sediments, heavy metals, and phosphorus from stormwater runoff. It features a base with inlet holes for even water flow, a removable top shell with a retention chamber, a one-way air valve, and a filter cylinder with three different media for targeted removal of contaminants. The system is customizable and can be fitted into a pre-assembled, high-strengthFRP system for easy installation and maintenance. The Xtream Protector is a part of the Xtreamfilter series, which maximizes water surface contact for high flow rates of clean water.

The Xtreamfilter is a highly efficient and comprehensive tertiary treatment filter that effectively removes TSS, phosphorus, nitrogen, gross pollutants, hydrocarbons, oils, and heavy metals. The filter is constructed with an outer FRP shell that surrounds a cylindrical cylinder filled with specially designed filtration media that targets specific contaminants using a range of filtration techniques. The water flows up the outer channel, horizontally through the dual filter media, and rises up the inner tube into the retention chamber before flowing out the outlet dropper pipe. The filter media is protected by a 1000-micron bag mesh and utilizes adsorption, precipitation, chemical filtration, physical filtration, and attachment techniques for removal. The outlet system can vary depending on the installation, with OSD in-situ concrete systems allowing for pipework concreted into the tank, or elevated PVC pipes, elbows, and tee systems. The system utilizes siphon filtration and self-cleaning techniques through backwash to ensure constant water flow and increase the lifespan of the filter media. Installation and maintenance are simple, and the system comes pre-assembled in a FRP-horizontal encasing. The Xtreamfilter is an exceptional filtration system suitable for various site demands.

Product Application

- Transport depots & loading bays

- Aircraft Aprons

- Car parks & shopping centers

- Recycling yards

- Heavy vehicle maintenance

Enquire with us

Today!

Call 1300 585 787