Stormbrake

Stormbrake Overview

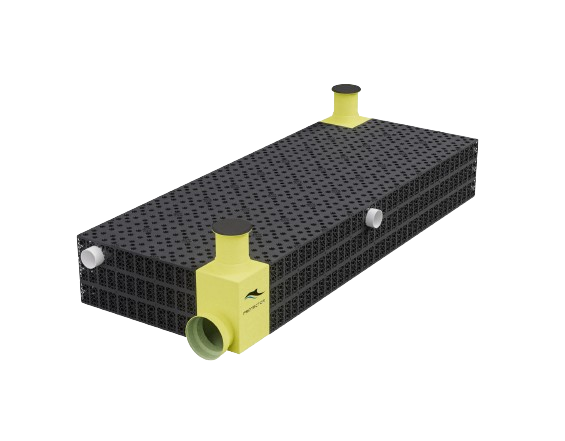

The StormBrake system is an innovative stormwater management system designed for a wide range of applications, including Onsite Detention (OSD), rainwater reuse, and infiltration. Made from durable polypropylene, this retention system features a modular design that allows for easy expansion and customization. It effectively combines biofiltration stormwater treatment with natural filtration techniques, using soil and compacted washed stone to remove sediment and nutrients from stormwater. By providing a sustainable water management solution, the StormBrake system not only ensures compliance with environmental standards but also promotes long-term efficiency in sediment removal and overall stormwater quality.

- Low-maintenance stormwater management system designed for minimal upkeep in Onsite Detention (OSD), rainwater reuse , and infiltration applications

.

- Durable polypropyleneconstruction resists corrosion and wear, reducing the need for frequent repairs.

- Modular retention system design allows for easy inspection and access, simplifying routine maintenance tasks.

- Natural biofiltration stormwater treatmentreduces the accumulation of debris, lowering maintenance frequency.

- Effective sediment removal system minimizes blockages, ensuring long-term performance with less maintenance intervention.

The StormBrake system is designed for easy and lightweight installation, making it an ideal choice for various stormwater management applications. Its modular polypropylene construction allows for straightforward handling and transport, reducing installation time and labor costs. The open-bottomed design facilitates seamless conjoining, enabling quick assembly and customization to fit specific site requirements. With fewer components and minimal heavy equipment needed, the StormBrake system can be efficiently installed in both urban and rural settings, ensuring a hassle-free setup process for contractors and installers.

The StormBrake system is an advanced stormwater management solution that integrates a Polypropylene (PP) retention system with efficient stormwater treatment capabilities. Designed with a single PP shell and an open-bottomed structure, the StormBrake system can be easily conjoined to create expansive configurations tailored to specific site requirements.

Key Features

- Modular Design: The system’s open-bottomed, single-shell design allows for seamless expansion, enabling the creation of large, custom configurations for diverse applications.

- Versatile Applications: Ideal for Onsite Detention (OSD), Retention, Rainwater Reuse, and Infiltration, offering flexibility in addressing various stormwater management needs.

- Dual Functionality: Simultaneously stores and filters stormwater, maximizing efficiency in both water management and treatment.

- Natural Filtration: Utilizes natural biofiltration techniques in combination with soil and compacted washed stone to effectively remove nutrients, sediment, and attached particles, ensuring high-quality water output.

- Sustainable Solution: By combining storage and filtration in one system, StormBrake promotes sustainability and reduces the need for separate stormwater treatment installations.

Applications of the StormBrake System:

– Infiltration Tanks: Facilitates the percolation of stormwater into the ground, aiding groundwater recharge.

– Rainwater Harvesting: Collects and stores rainwater for non-potable uses like irrigation and landscaping.

– Re-Use Tanks : Efficiently stores water for reuse, reducing the need for municipal water supplies.

– Detention Tanks (Attenuation) : Temporarily holds stormwater to manage peak flow rates and mitigate flooding.

– Soak Wells: Provides an efficient solution for managing stormwater runoff and promoting infiltration.

– Leach Drains: Supports the dispersal of wastewater or stormwater into the ground, minimizing surface runoff.

– Drainage Channels: Effectively manages and directs stormwater, preventing erosion and waterlogging.

-Lightweight Structural Fill : Acts as a stable and lightweight fill material, suitable for various construction needs.

-Rooftop Gardens : Supports the creation of green roofs by providing drainage and water retention capabilities.

-Planter Boxes: Enhances urban greenery by supporting water management in raised garden beds.

-Irrigation: Provides a sustainable water source for irrigation systems, promoting water conservation.

These versatile applications make the StormBrake system a comprehensive solution for various stormwater management needs across different environments.

OUR PROJECTS

THE GANGARRI SOLAR PROJECT

Project Description

THE GANGARRI SOLAR PROJECT

Project Description

Coastal View Development Lakes Entrance Project

Project Description

Coastal View Development Lakes Entrance Project

Project Description

Child Care Centre Project

Project Description

Child Care Centre Project

Project Description

Puma Energy

Project Description

Puma Energy

Project Description

TRIPLE CHAMBER SEPARATOR Diameter: 2200mm Total length: 11,000mm Oil Capacity: 9000L Silt capacity: 1000L Coalescer Filter Type: R6 Filter flow rate: 35L/sHYD.015.3C-R2.A HydroProtector

TRIPLE CHAMBER SEPARATOR Diameter: 1500mm Total length: 6000mm Oil Capacity: 1500L Silt capacity: 300L Coalescer Filter Type: R2 Filter flow rate: 5L/s

FAQ'S

The primary function of the StormBrake system is to manage stormwater by temporarily storing (Onsite Detention or OSD) and retaining water. It helps control peak flow rates to reduce flooding risks while allowing for the gradual release or reuse of stored water.

The StormBrake system offers several significant benefits:

– Quick and Easy Installation: The lightweight design reduces site access delays and eliminates the need for cranes or lifting equipment, allowing for on-site assembly.

– Modular Flexibility : Easily create any shape and size to suit individual site and project requirements.

-Maintenance-Free : Each Stombrake should have a Filter on the inlet so that all debris and sediment are removed by pre-filtration, and materials are resistant to moulds, algae, soil-borne chemicals, and bitumen.

– High Water Capacity : One cubic metre of Flo Tank modules can hold up to 950 litres of water.

– Efficient Excavation : Reduces excavation and disposal by two-thirds compared with conventional soak wells, thanks to a 95% void surface area and high flow-through volume.

– Easily Transportable : The system can be supplied unassembled, making it ideal for delivery to remote areas.

The StormBrake system is designed for easy installation. Its lightweight and modular components can be quickly assembled and conjoined, reducing installation time and labor costs. Multiple access points, including manway access at the inlet and outlet, further simplify maintenance. This makes it an efficient choice for both new projects and retrofits.

The StormBrake system is designed for easy maintenance through multiple access points:

– Manway Access: Located at both the inlet and outlet, these provide entry points for inspection and maintenance activities, allowing direct access for jetting and cleaning.

-Stormbrake Access : Each level of the Crates within the system can be accessed via the Stormbrake, ensuring thorough inspection and maintenance across all levels.

-Removable GP Screen : The lowest level of the system is equipped with a removable GP screen, facilitating debris removal and ensuring the system operates efficiently.

1. Manway Access: Located at both the inlet and outlet, these provide entry points for inspection and maintenance activities, allowing direct access for jetting and cleaning.

2. Stormbrake Access: Each level of the Crates within the system can be accessed via the Stormbrake, ensuring thorough inspection and maintenance across all levels.

3.Removable GP Screen: The lowest level of the system is equipped with a removable GP screen, facilitating debris removal and ensuring the system operates efficiently.

Yes, the StormBrake system is suitable for residential areas,

as well as commercial and industrial sites. Its adaptable design and efficient stormwater management capabilities make it an excellent choice for various environments, helping to mitigate flood risks and support rainwater reuse.

The StormBrake system stores rainwater, which can then be reused for non-potable purposes such as irrigation, landscaping, and other water-conserving practices. By capturing and retainingrainwater, the system reduces the demand on municipal water supplies.

Yes, the StormBrake system promotes sustainable water management by combining storage, filtration, and reuse in one solution. It helps improve water quality, supports groundwater recharge through infiltration, and reduces the environmental impact of stormwater runoff. The easy maintenance design ensures it remains efficient and environmentally friendly over its long lifespan.

It is recommended to contact an Protector Australia representative, who can assist with calculations and determine the number of Modules required based on the water capacity of the tanks and the volume of water to be captured by the system.