Because we think

nature is worth saving...

At Protector, we are focused on improving the quality of our waterways by supplying products that are designed to capture and contain pollution in stormwater runoff for many applications. Contaminants such as hydrocarbons, suspended solids, plastic rubbish, and dissolved nutrients are removed by utilizing absorption, retention, filtration, and capture processes. These stormwater systems will deliver cleaner water back into the environment, saving nature for future generations.

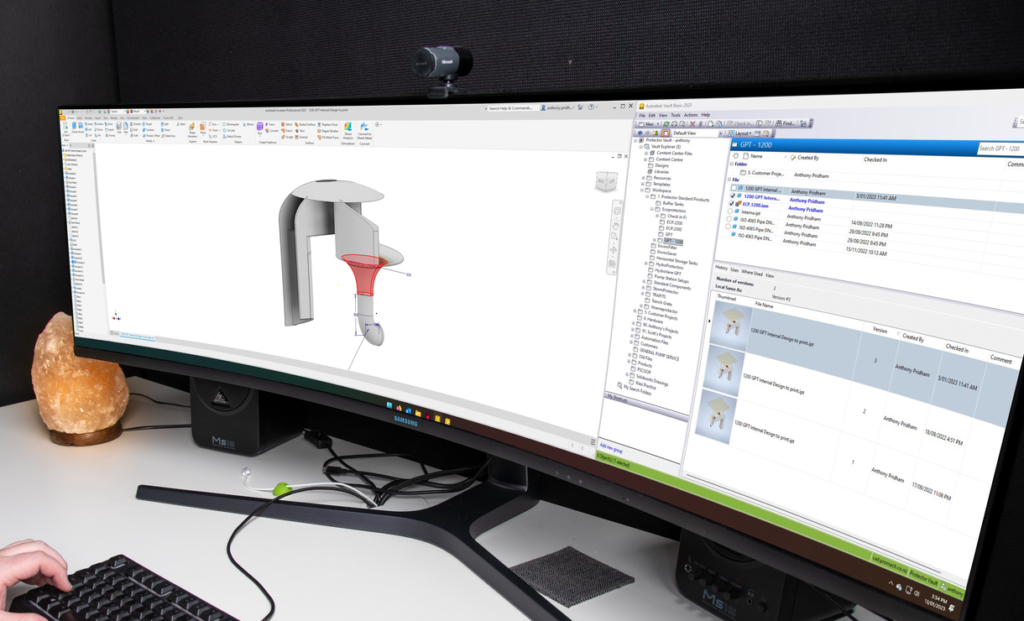

Protector is an Australian family-owned and operated stormwater treatment and fiberglassing company. Protector’s 18 years of fabrication experience is a result of continuous improvement in product design and manufacturing innovation.

Quality control procedures ensure each product is manufactured to specification and post-production, each unit is inspected and factory tested to industry standards.

Protector products are constructed using the advanced chop hoop filament winding process which ensures circumferential as well as longitudinal strength. Every Protector product has a smooth molded resin-rich inner corrosion barrier layer and an external resin barrier. Being manufactured in FRP (Fibre Reinforced Plastic) Protector products are light, easy to handle, and easy to install.

FRP composites are a sustainable material that is reflected through its physical characteristics resulting in longer service. The weight-saving advantages lower construction and transport costs, reducing environmental impact. FRP products are high-strength and are far more resistant to the effects of ageing, weathering, and degradation in severe environments. Maintenance is improved by the smooth internal molded finish providing excellent protection against scum accumulation. Fiber Reinforced Plastic is not susceptible to rust and offers excellent corrosion resistance.

Enquire with us

Today!

Call 1300 585 787