STORMPROTECTOR

- HIGH-PERFORMANCE SEPARATOR AVAILABLE IN BOTH IN-LINE AND OFF-LINE CONFIGURATIONS

- EASY ACCESS FOR SCHEDULED MAINTENANCE

- REMOVAL OF GROSS POLLUTANTS AND SEDIMENT DOWN TO 3MM

- STRONG FRP CONSTRUCTION WITH WEIGHT SAVING ADVANTAGE

STORMPROTECTOR

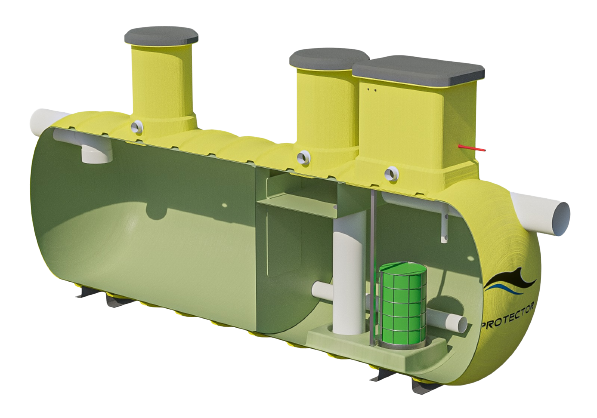

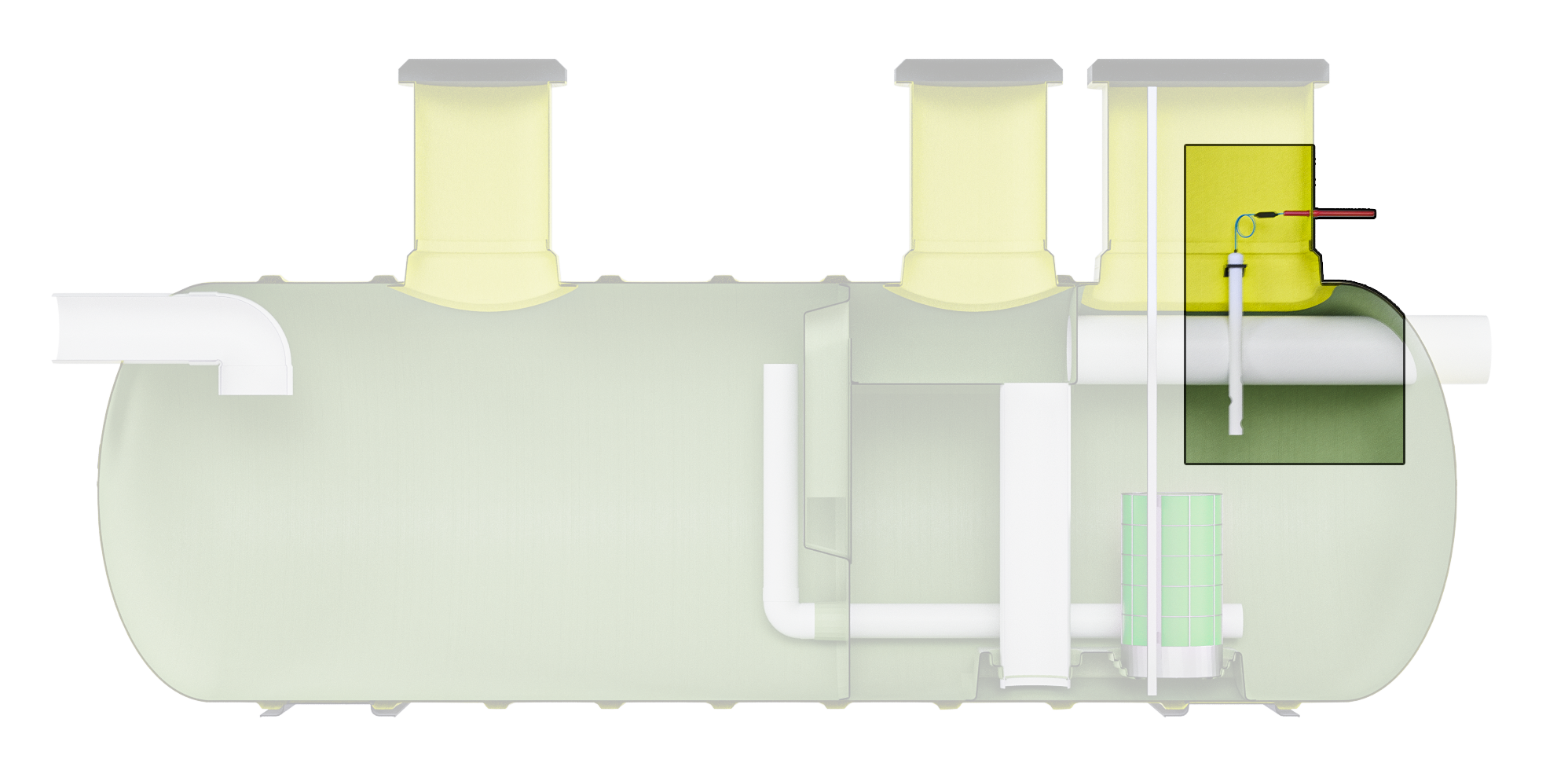

The Stormprotector is a high-performance Class-1 separator available inboth in-line and off-line configurations. The in-line system has an internalbypass that allows it to be retrofitted in existing drainage systems, makingit ideal for medium-risk catchments. The system has two horizontallyconfigured chambers equipped with a coalescer unit that promotes theseparation of total suspended solids (TSS), light liquids, and pollutants. The system has a retention period that provides quiescent conditions, which ensures efficiency. The off-line system is installed on a low flowline and is designed to treat a minimum of a 1 in 3 month ARI (4EY), with bypass options for flows above the design treatment flow rate to avoidflooding and transport of previously captured pollutant.

The Stormprotector is highly efficient at removing TSS and treating oily water and hydrocarbon runoff from medium-risk catchments, thanks o its advanced design. The separator utilizes a gravity-enhancing coalesce unit that facilitates particle sedimentation, particularly of these and fraction, and ensures that the sediment is retained in a silt trap chamber below the separator. The system has an oil trap mechanism that prevents the movement of any oil that isn’t dissolved and retained in the filter elements. The Stormprotector is an easy-to-install and maintain solution for medium-risk commercial and industrial applications.

WHY INSTALL A STORMPROTECTOR

The Stormprotector is installed in medium risk zones to effectively remove pollutants from stormwater runoff before it enters waterways or storage systems. The StormProtector is designed to remove total suspended solids (TSS), light liquids, and hydrocarbons, making it an effective solution for managing water quality in medium-risk commercial and industrial applications. Installing a Stormprotector can help to protect the environment and comply with regulatory requirements for stormwater management. The system is also flexible, with both in-line and off-line configurations available, and can be retrofitted into existing drainage systems, making it a convenient option for upgrading existing infrastructure. Additionally, the Stormprotector is easy to install and maintain, with features such as an access manway for filter maintenance.

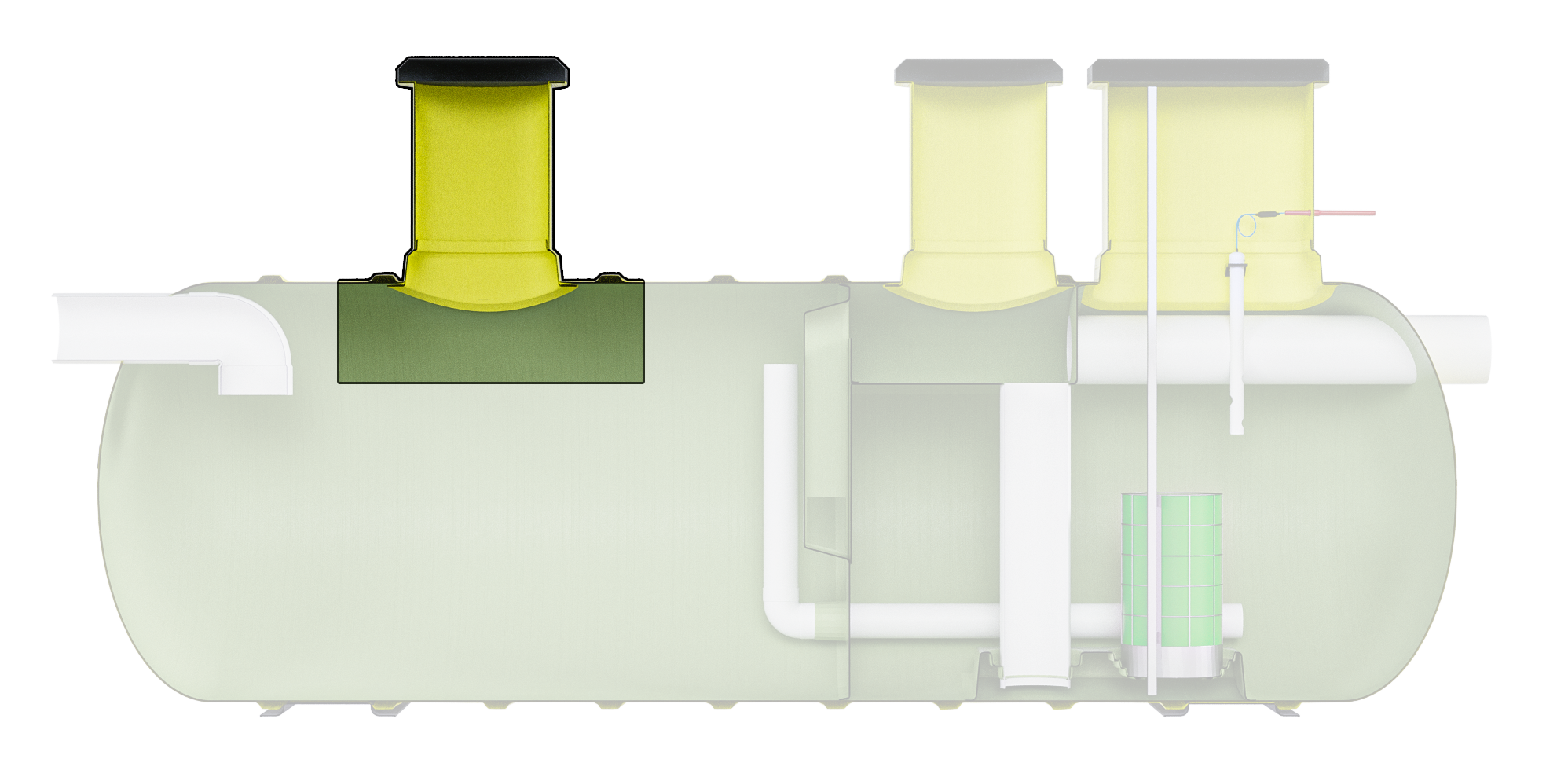

Step One

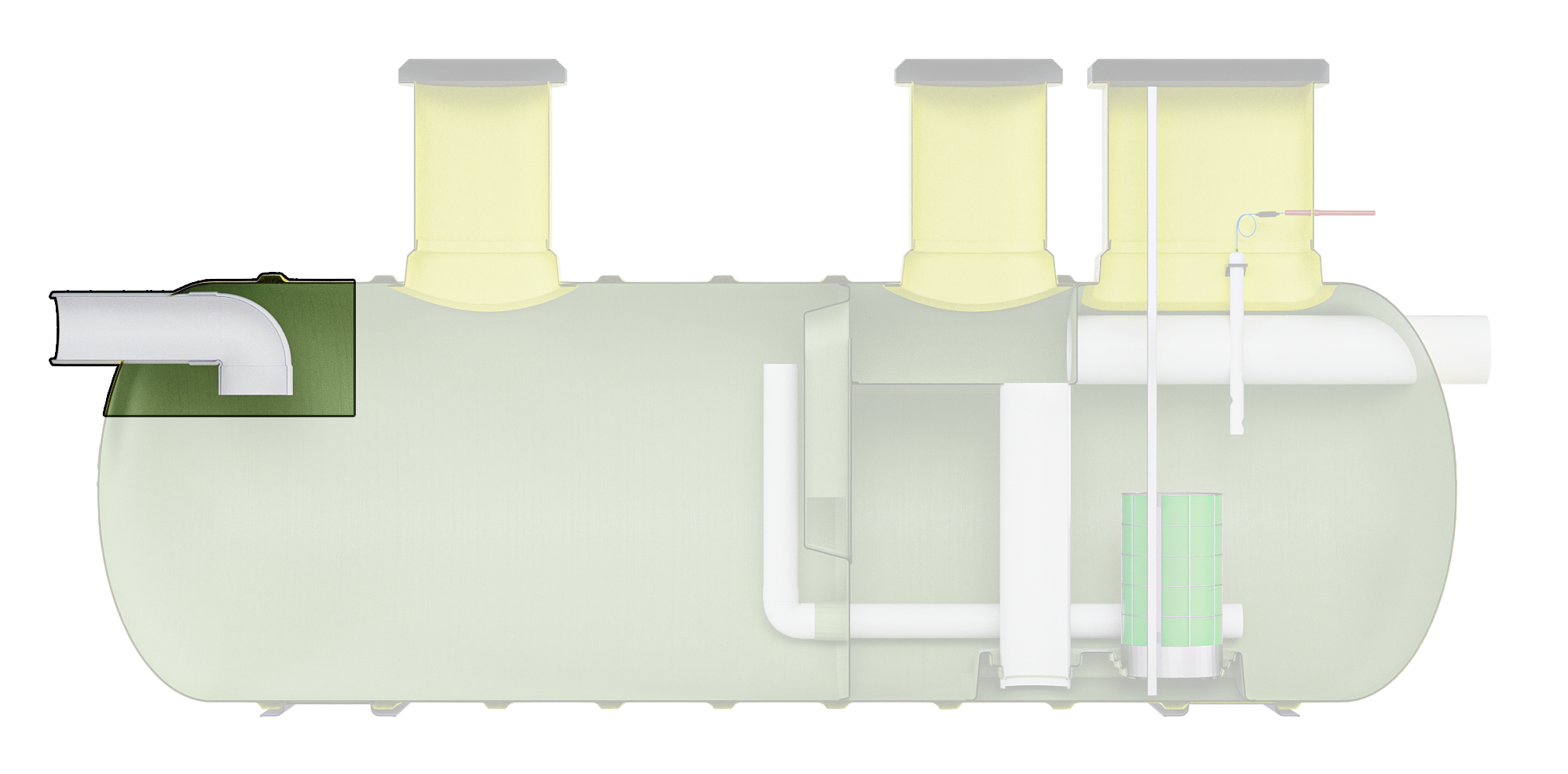

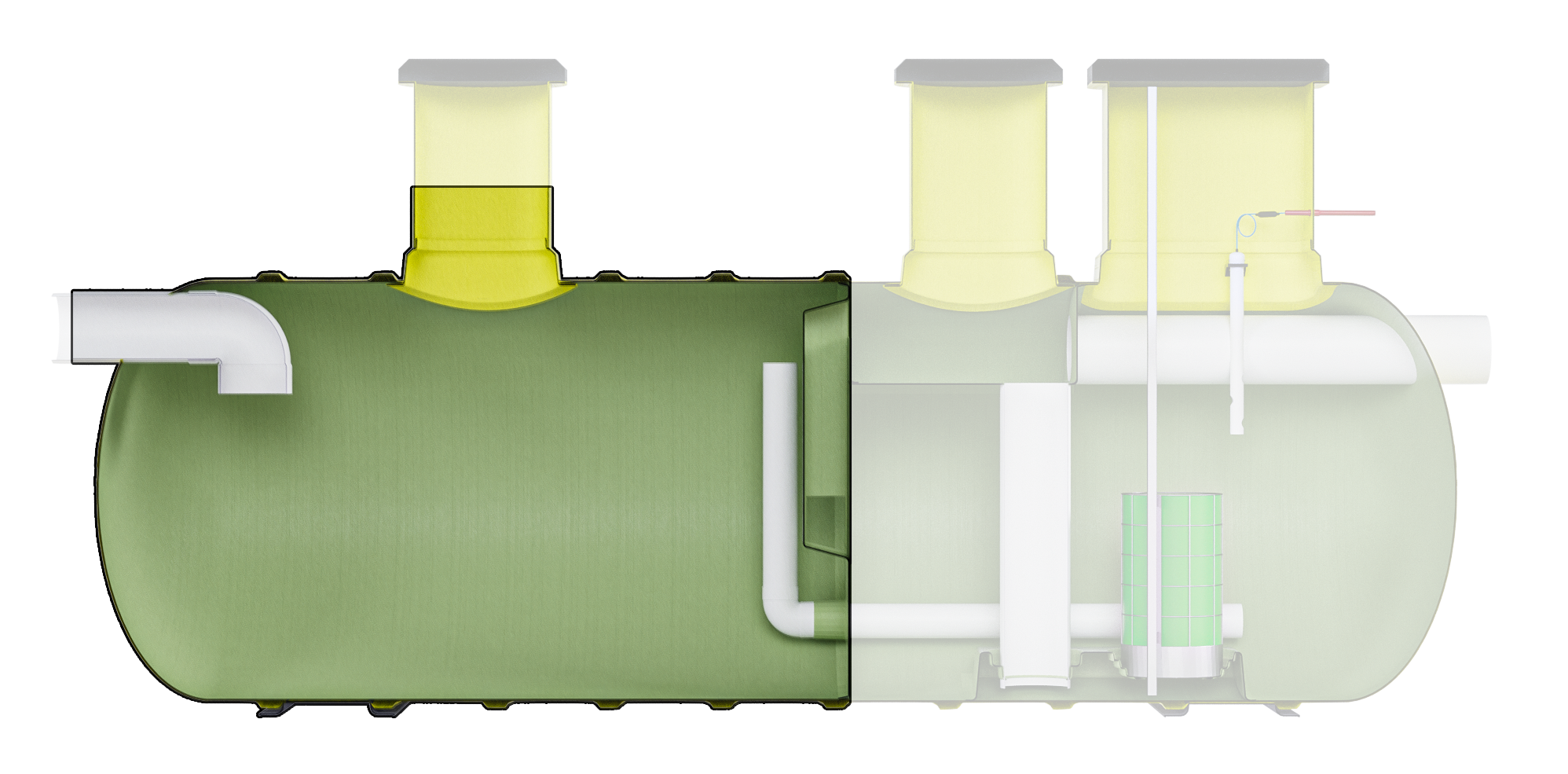

FLAME TRAP INLET

The inlet pipe features a flame trap which works by eliminating air from the liquids entering the primary chamber.

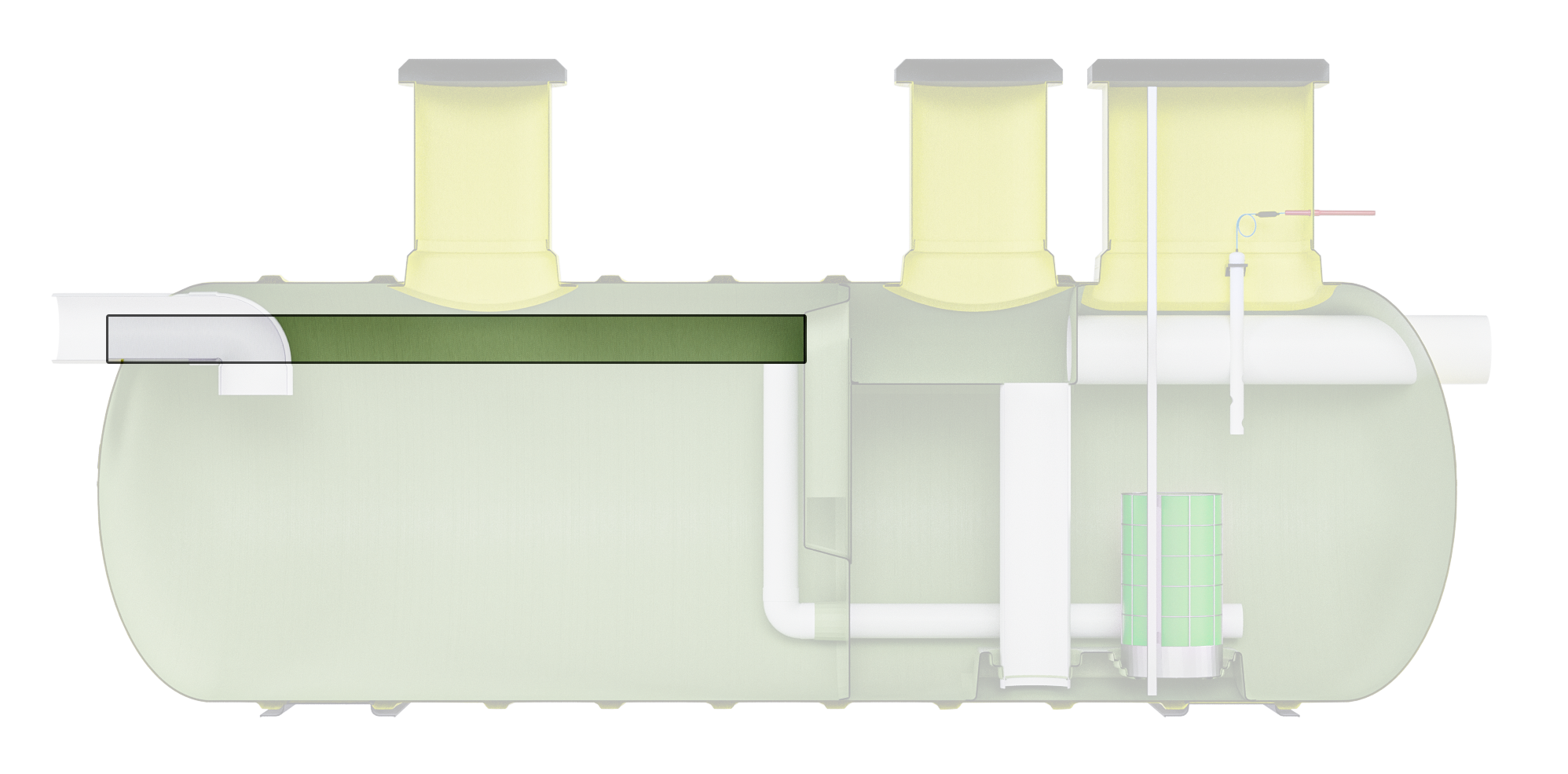

Step Two

PRIMARY CHAMBER

The primary chamber of the Stormprotector is designed to slow down and separate pollutants from Stormwater runoff, allowing dense particles to settle at the bottom of the chamber and the lighter fluids and debris to rise to the surface while the cleaner water flows into the secondary chamber for further treatment.

Step Three

TRASH, OIL AND SLUDGE PUMPOUT ACCESS

The Stormprotector is easily maintained due to its trash, oiland sludge pumpout access, providing easy and efficient access for regular maintenance and cleaning.

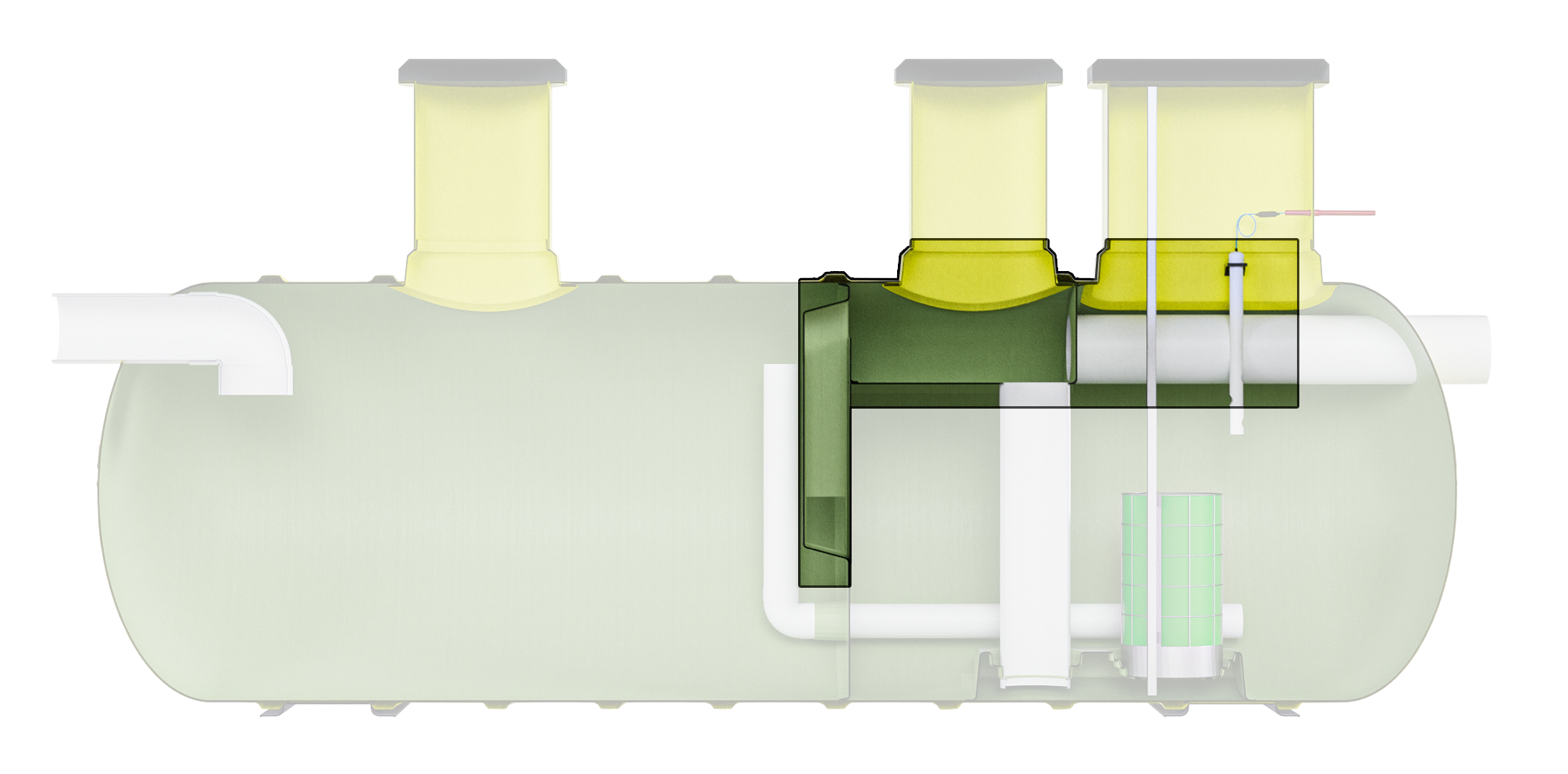

Step Four

OIL CAPTURE

Captured hydrocarbons rise to the surface of the storage chamber and are retained behind a weir which stops them from flowing into the secondary chamber without resuspension during high flow events.

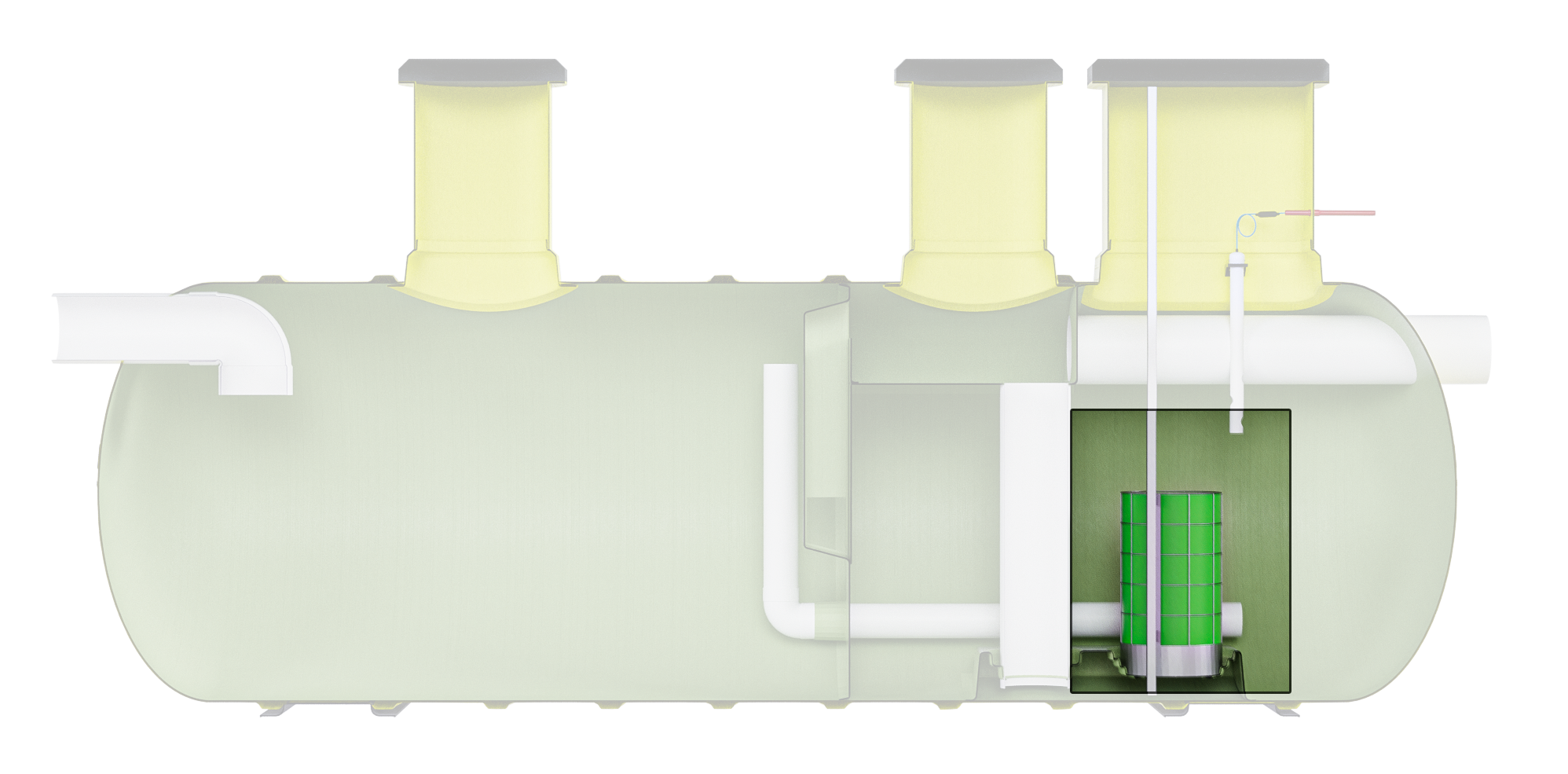

Step Five

COALESCER FILTER UNIT

The secondary chamber is fitted with a finely perforated coalescing unit which removes the remaining globules of light liquid to a certified 5mg/l. The coalescing unit is installed on guide rails for ease of installation and maintenance.

Step Six

BYPASS AND OUTLET CHAMBER

The Stormprotector has a max flow bypass that allows water to discharge freely over the weir during large stormwater inflows to prevent flow restriction.

Step Seven

OIL PROBE AND CONTROL PANEL

The oil probe and control panel are crucial components in monitoring and maintaining oil spills. The probe detects any oil leaks and sends signals to the control panel, which alerts the maintenance team.

APPLICATIONS OF THE STORMPROTECTOR

- Carparks and Shopping centers

- Transport depots

- Aircraft Aprons

- Maintenance and storage areas

- Tunnels and highways

- Recycling yards

- Industrial,comeercial,residential estates

STORMPROTECTOR SPECIFICATIONS

| Model ID | TREATMENT FLOW RATE (L/S) | BYPASS FLOW RATE (L/S) | SILT CAPACITY (L) | WORKING CPACITY (L) | UNIT LENGHT (L) | UNIT DIA (mm) | STANDARD PIPEWORK DIA | DRAWING |

|---|---|---|---|---|---|---|---|---|

| SP.2.DC.R2-1 | 2 | 90 | 200 | 791 | 1,100 | 1050 | 150 | Download |

| SP.4.DC.R2-1 | 4 | 90 | 20 | 165 | 2,100 | 1050 | 150 | Download |

| SP.8.DC.R2-1 | 8 | 180 | 820 | 2,984 | 3,000 | 1200 | 225 | Download |

| SP.13.DC.R4-1 | 13 | 250 | 1,300 | 4,896 | 2,400 | 1500 | 375 | Download |

| SP.15.DC.R4-1 | 15 | 250 | 1,500 | 5,616 | 3,750 | 1500 | 375 | Download |

| SP.20.DC.R4-1 | 20 | 480 | 2,000 | 7,495 | 3,350 | 1850 | 450 | Download |

| SP.30.DC.R5-1 | 30 | 480 | 2,300 | 11,228 | 5,450 | 1850 | 450 | Download |

| SP.40.DC.R6-1 | 40 | 480 | 4,100 | 14,950 | 7,500 | 1850 | 450 | Download |

| SP.50.DC.R5-2 | 50 | 480 | 5,100 | 18,678 | 8,000 | 1850 | 450 | Download |

| SP.60.DC.R5-2 | 60 | 480 | 6,100 | 22,405 | 9,550 | 2550 | 450 | Download |

| SP.70.DC.R5-2 | 70 | 660 | 7,100 | 26,224 | 7,900 | 2200 | 750 | Download |

| SP.80.DC.R6-2 | 80 | 660 | 8,100 | 29,888 | 8,850 | 2200 | 750 | Download |

| SP.100.DC.R5-3 | 100 | 660 | 10,200 | 37,392 | 11,000 | 2500 | 750 | Download |

| SP.110.DC.R5-3 | 110 | 1400 | 11,200 | 10,000 | 10,000 | 2500 | 900 | Download |

| SP.120.DC.R6-3 | 120 | 1400 | 12,200 | 45,131 | 10,800 | 2500 | 900 | Download |

| SP.150.DC.R5-4 | 150 | 1400 | 16,000 | 56,116 | 13,350 | 2500 | 1,050 | Download |

| SP.180.DC.R6-4 | 180 | 1600 | 18,300 | 67,949 | 11,000 | 3000 | 1,200 | Download |

| SP.200.DC.R6-4 | 200 | 2000 | 20,500 | 76,029 | 9,000 | 3500 | 1,200 | Download |

| SP.250.DC.R7-4 | 250 | 2000 | 25,500 | 93,825 | 11,000 | 3500 | 1,200 | Download |

| SP.300.DC.R7-5 | 300 | 2000 | 30,500 | 112,511 | 13,100 | 3500 | 1,200 | Download |

| SP.350.DC.R7-5 | 350 | 2000 | 35,500 | 130,751 | 15,200 | 3500 | 1,200 | Download |

Product Drawing

Enquire with us

Today!

Call 1300 585 787

Southern Highlands 1 Government Road, Braemar, NSW, 2575

Email: sales@protector.com.au

Phone: 1300 585 787

Give us a call or drop by anytime, we endeavour to answer all enquiries within 24 hours on business days.

- TRAP-IT- GROSS POLLUTANT

- ECOPROTECTOR - HIGH CAPACITY GROSS POLLUTANT TRAP

- TORNADO - HIGH FLOW CONTINUOUS DEFLECTION SEPERATION GPT

- HYDROPROTECTOR - CLASS 1 HYDROCARBON SPILL CONTAINMENT AND OIL SEPERATION

- STORMPROTECTOR - MEDIUM RISK STORMWATER TREATMENT

- BIOPROTECTOR - PHYSICAL AND BIOLOGICAL FILTRATION

- XTREAMFILTER - MODULAR NUTRIENT FILTER SYSTEM

- ENVIROPROTECTOR - DUAL CHAMBER UPFLOW TERTIARY FILTRATION

- ENVIROSAVE - TRIPLE CHAMBER GPT WITH OFFLINE FILTRATION

- STORMBRAKE - MODULAR BIOFILTRATION RETENTION SYSTEMS

- HYDROVAULT - HIGH CAPACITY STORAGE AND RETENTION SYSTEMS

© 2024 Protector. All rights reserved.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.

Please fill out the following details so we can send the document to you.